Phenolic Resin For Printing Ink

Product Details:

- Type Phenolic Resin

- Grade Industrial Grade

- Application Printing Ink

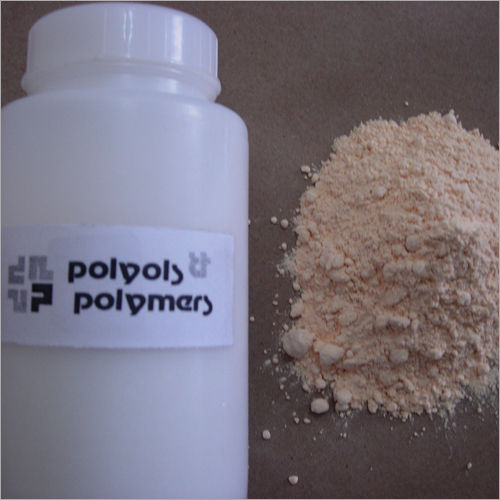

- Color Pink

- Click to View more

Phenolic Resin For Printing Ink Price And Quantity

- 135 INR/Kilograms

- 25 Kilograms

Phenolic Resin For Printing Ink Product Specifications

- Pink

- Printing Ink

- Phenolic Resin

- Industrial Grade

Phenolic Resin For Printing Ink Trade Information

- Cash in Advance (CID) Cash Advance (CA)

- 25 Kilograms Per Day

- 2-3 Days

- Poly Bag

- Australia Eastern Europe Western Europe Central America Middle East South America Asia North America Africa

- All India

Product Description

Phenolic Resin for Printing Ink

| PART 1 /RESIN | |

| Chemical Classification | Phenol Formaldehyde Resin |

| Physical Form | Lump ( Part 1) |

| Color | Yellow to Reddish Brown |

| Melting Point (Capillary) | 72 C 80 C |

| PART 2/CATALYST | |

| Physical Form | Crystalline Powder (Part 2) |

| Color | White |

| PART 1 + PART 2 | |

| Part 2 Catalyst / Hexa Content | 6% - 9% of (Part 1 + Part 2) |

| Hot Plate Cure @ 160 C | 60 85 sec |

Properties and Usage

POLYTONE PF 133 C is a phenol formaldehyde resin to be mixed with Hexa or Part 2 Catalyst.

POLYTONE PF 133 C (Part 1 + 2) effortlessly penetrates and adheres to the structure of many organic and inorganic fillers and reinforcements which makes it an ideal candidate for various end uses.

Usage Suggestions :

Part 1 should be powdered and mixed with Part 2 as per suggested loading quantity. Cured at necessary temperature.

Part 1 + Part 2 to be mixed and dissolved in Alcohol/Ketone to prepare a solution. Solution to be mixed with filler etc or applied on surface and cured.

Industrial: Molding Powder, Molding Compounds, Abrasive, Grinding Wheels, Binder, Foundry Binder, Housings.

Applications: Laminates, Corrugated Box Manufacture, Ply Wood, Particle Board, Hard Board, Binder in Pyrotechnic Compositions and many more

Resin/ Part 1 is applicable in Ink Industry.

Solubility: POLYTONE AP 133 is soluble in alcohols, esters, ketones, aromatic and aliphatic chlorinated hydrocarbons.

Packaging: Available in 25 Kgs Standard Bags ( Resin/Part 1)

Shelf Life: Store under cool dry conditions. It is recommended that the material be used within 12 months from the date of manufacture (Resin/Part 1).

Other Products in 'Phenol Formaldehyde Resins' category

|

POLYOLS & POLYMERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |