Low Viscosity Ketonic Resin

Product Details:

- Type Ketonic Resin

- Grade Industrial Grade

- Application For Industrial Use

- Color White

- Click to View more

Low Viscosity Ketonic Resin Price And Quantity

- 25 Kilograms

- 120 INR/Kilograms

Low Viscosity Ketonic Resin Product Specifications

- Industrial Grade

- Ketonic Resin

- For Industrial Use

- White

Low Viscosity Ketonic Resin Trade Information

- Cash in Advance (CID) Cash Advance (CA)

- 25 Kilograms Per Day

- 2-3 Days

- Yes

- Poly Bag

- Australia North America Eastern Europe Africa Western Europe Central America Middle East South America Asia

- All India

Product Description

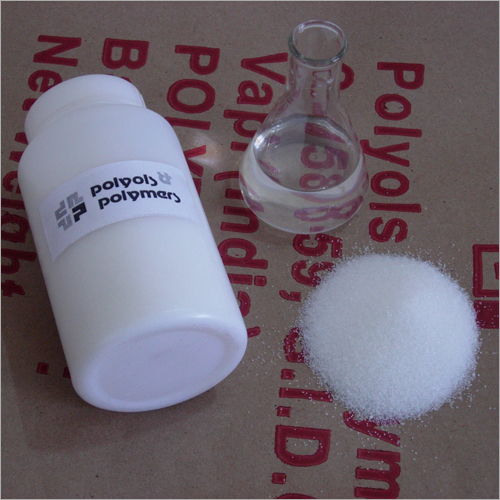

Low Viscosity Ketonic Resin

| TECHNICAL DATA | POLYTONE K-93 |

| Chemical Classification | Cyclohexanone Formaldehyde Resin |

| Physical Form | Pearl Shaped Granular Solid |

| Softening Point (Ball & Ring Method ) | 98 C 103 C |

| Viscosity of 50% solution in Industrial Spirit at 25 C by B 4 Ford Cup | 15 - 17 sec |

| Iodine No of 50% solution in Iodine No of 50% solution in | 1.0 Max |

| Hydroxyl Value | 265-285 mg KOH / gm resin |

| Acid Value | 1 mg KOH / gm resin ( Max ) |

Properties & Usage: These resins are highly effective in imparting gloss, adhesiveness, leveling and also in increasing the solid content leading to a reduction in the VOC. The hydroxyl polarity leads to better adhesion and wetting of pigments and surfaces. POLYTONE K -93 is used in the manufacture of all types of nitrolacquers and are useful in the manufacture of PVC lacquers and for polishing lacquers and finishes for the surface treatment of wooden furniture and articles. POLYTONE K- 93 is also useful in heat seal coatings, primer and base coatings, gasoline resistant coatings, nail lacquers etc.

Industrial Applications: Flexographic Inks, Gravure Inks, Lamination Inks, Ball Point Inks, Lacquers, Offset Inks, PU-systems, Nitro Cellulose Paints, Varnishes, Heat Seal Coating, Primer and Base Coatings, Gasoline resistant coatings, Nail Lacquers and many more.

Solubility: POLYTONE K 93 is soluble in alcohols (not in methanol), ketones, esters, glycol ether acetates, as well as in some aromatic & chlorinated hydrocarbons. They are however not soluble in water and in aliphatic hydrocarbons

Compatibility: POLYTONE K 93 is compatible with different types of nitrocellulose, benzyl cellulose, ethyl cellulose, cellulose acetate, polyvinyl chloride, chlorinated rubber, as well as in many synthetic resins e.g. alkyd resins, pthallic resins, UF resins, polyvinyl butyryl resins, polyamide, phenol formaldehyde condensation resins etc and a multitude of plasticizers.

Packaging: Available in 25 Kg bags

Shelf Life: Store under cool dry conditions. It is recommended that the material be used within 12 months from the date of manufacture

Other Products in 'Polyketone Resin' category

|

POLYOLS & POLYMERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |