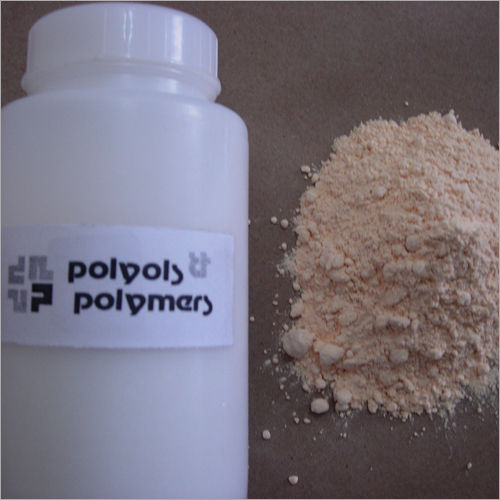

Phenolic Resin Lump

Product Details:

- Type Phenolic Resin

- Grade Industrial Grade

- Application Moulding Powder , Printing Ink

- Color Pink

- Click to View more

Phenolic Resin Lump Price And Quantity

- 135 INR/Kilograms

- 25 Kilograms

Phenolic Resin Lump Product Specifications

- Moulding Powder , Printing Ink

- Industrial Grade

- Phenolic Resin

- Pink

Phenolic Resin Lump Trade Information

- Cash Advance (CA) Cash in Advance (CID)

- 25 Kilograms Per Day

- 2-3 Days

- Poly Bag

- Australia North America Eastern Europe Western Europe Central America Middle East South America Asia Africa

- All India

Product Description

We are distinguished in the market as one of the trusted organizations engaged in offering Phenolic Resin Lump. It is formaldehyde resin developed to be mixed with Hexa or part 2 catalyst. This resin effortlessly penetrates and adheres to the structure of many organic and inorganic fillers. It is used in laminates, corrugated box manufacture, ply wood, particle board, hard board, binder in pyrotechnic compositions and many more. Phenolic Resin Lump is available in different quantity packaging options and at affordable prices.

Features:

- Yellowish to reddish brown

- Soluble in alcohols

- Melts at 85 °C

Phenolic Resin Lump

|

PART 1 /RESIN |

|

|

Chemical Classification |

Phenol Formaldehyde Resin |

|

Physical Form |

Lump ( Part 1) |

|

Color |

Yellow to Reddish Brown |

|

Melting Point (Capillary) |

70° C – 85 ° C |

|

PART 2/CATALYST |

|

|

Physical Form |

Crystalline Powder (Part 2) |

|

Color |

White |

|

PART 1 + PART 2 |

|

|

Part 2 Catalyst / Hexa Content |

7% - 9% of (Part 1 + Part 2) |

|

Inclined Plate Flow@125° C |

30 – 45 mm |

|

Hot Plate Cure @ 160° C |

40 – 65 sec |

Properties and Usage

POLYTONE™ PF 132 C is a phenol – formaldehyde resin to be mixed with Hexa or Part 2 Catalyst.

POLYTONEâ„¢ PF 132 C (Part 1 + 2) effortlessly penetrates and adheres to the structure of many organic and inorganic fillers and reinforcements which makes it an ideal candidate for various end uses.

Usage Suggestions :

Part 1 should be powdered and mixed with Part 2 as per suggested loading quantity. Cured at necessary temperature.

Part 1 + Part 2 to be mixed and dissolved in Alcohol/Ketone to prepare a solution. Solution to be mixed with filler etc or applied on surface and cured.

Industrial: Molding Powder, Molding Compounds, Abrasive, Grinding Wheels, Binder, Foundry Binder, Housings.

Applications: Laminates, Corrugated Box Manufacture, Ply Wood, Particle Board, Hard Board, Binder in Pyrotechnic Compositions and many more

Resin/ Part 1 is applicable in Ink Industry.

Solubility: POLYTONEâ„¢ AP 132 is soluble in alcohols, esters, ketones, aromatic and aliphatic chlorinated hydrocarbons.

Packaging: Available in 25 Kgs Standard Bags ( Resin/Part 1)

Shelf Life: Store under cool dry conditions. It is recommended that the material be used within 12 months from the date of manufacture (Resin/Part 1).

Other Products in 'Phenol Formaldehyde Resins' category

|

POLYOLS & POLYMERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |